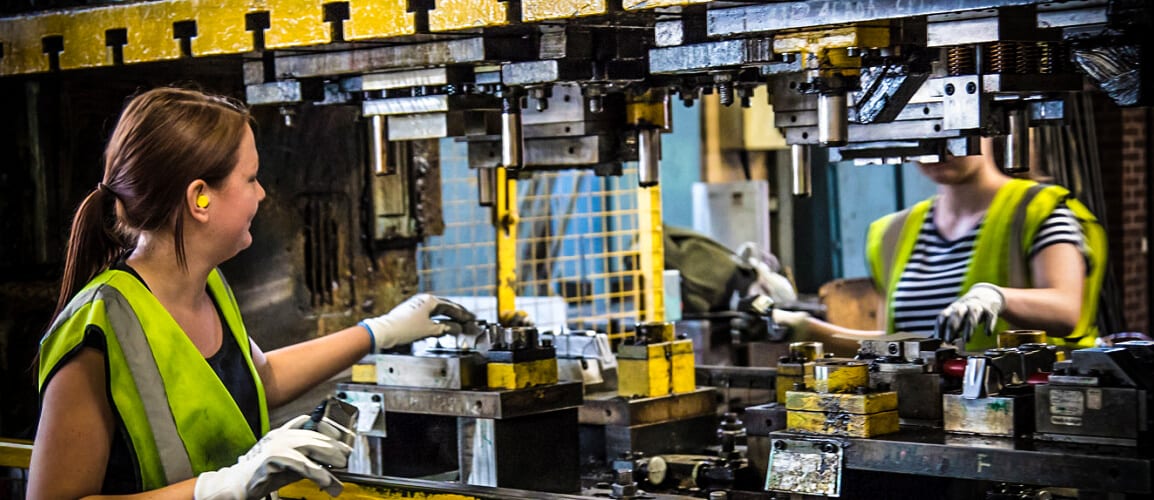

First of all, Pressmark turns ideas into finished products. Next, we combine proven engineering with modern tooling to deliver on time. Therefore, every project meets the exact specification. Finally, you can request a quote today to see how we can help.

Across industries, we support a wide range of sectors. For example, we work in automotive, yellow goods, white goods, construction, rail, and defence. Because of this, our knowledge can be applied across industries. In addition, we share best practice so that customers benefit from proven methods and efficient delivery.

Automotive

In the automotive sector, we make complex steel and aluminium pressings.

Yellow Goods

Additionally, we produce heavy-duty pressings and fabrications.

White Goods

Our white goods expertise includes stainless-steel and coated pressings.

Construction Industry

Also, we create pressed extrusions for curtain walling.

Rail Industry

Similarly, we deliver lightweight pressings for unique products.

Aerospace & Defence

Finally, we supply steel, aluminium and titanium pressings.

About Us

To begin with, Pressmark Pressings helps companies create and improve products through long-lasting, two-way partnerships. For instance, we work side by side with customers to plan projects that deliver the right parts on time. Therefore, efficiency remains essential in today’s market.

Moreover, our team offers sustainable and custom production options. As a result, we only use trusted suppliers who meet our IATF 16949 standards. Consequently, customers gain consistent parts, reliable schedules, and clear updates from start to finish. Finally, our approach ensures confidence from the first discussion through to delivery.

Company Background

Pressmark was founded in 1972 with a clear vision: to provide reliable pressed solutions for demanding industries. Since then, we have grown steadily by combining technical expertise with strong customer partnerships. As a result, we now supply millions of components each year to global brands.

In addition, our team invests in continuous training so every project benefits from modern skills and proven methods. Meanwhile, our central UK location means deliveries are quick and efficient. For example, customers in automotive and aerospace rely on us for just-in-time supply.

Consequently, quality and delivery performance remain industry-leading. We also keep things simple: parts are strong, dependable, and built to last. Finally, we continue to invest in new technology and sustainable practices. In conclusion, Pressmark remains focused on creating long-term value for our customers and their supply chains.

What has been said

Their work is of such outstanding quality, they are clearly experts in their field.

Brian & David Hobbs

For any manufacturing task, Pressmark are by far the most innovative in the industry.

Ben Scott

The creativity we encountered throughout was simply world class.

Matt and Lisa Collins

There is incredible peace of mind knowing that you’re in the hands of professionals.

Kerry-Ann Phillips

We help customers integrate technology and scale their production. Meanwhile, we make sure quality and value are never compromised.

Our Executive Team

Les Wilkins

Chairman

John Nollett

Chief Executive

Alan Gardner

Financial Director

Why Pressmark

Pressings are produced with proven processes and controlled checks. Furthermore, tooling is maintained in-house to keep quality steady. In addition, our supply base is audited and traceable.

As a result, customers experience consistent outcomes from batch to batch. For example, they rely on us for dependable lead times. Meanwhile, our central location supports efficient logistics. Similarly, clear updates keep projects on track.

Therefore, programmes move smoothly from idea to production without drama. Finally, our team is always ready to support your next project.

Contact Pressmark

We are always interested in new projects, whether large or small. Consequently, we encourage you to get in touch with our team. You can call (+44) 1827 716381 or send us an e-mail. Alternatively, if you already have a project in mind, request a quote, and we will review your proposal quickly. Finally, we look forward to supporting your success.