T he automotive industry faces unprecedented challenges in its supply chain management. This is due to factors such as raw material shortages, transportation disruptions, energy price hikes, currency fluctuations and pandemic lockdowns. These challenges have exposed the vulnerabilities of the current supply chain model. The existing supply chain relies heavily on just-in-time inventory practices and global sourcing of critical components such as semiconductors.

Read morePressmark utilise sensors to collect data and improve business processes

T he Manufacturing Information Platform (MIP) created by WMG, part of the University of Warwick, has been helping Pressmark collect data to improve its manufacturing processes. So far, the technology has helped the business analyse machine downtime, discover the bottleneck and change the process to become more time-efficient.

Atherstone based high-quality metal pressings firm Pressmark has been continuously improving business throughout their longevity, regardless of challenges brought on by the pandemic. With the knowledge and capability of supporting a wide variety of clients, the firm strives to improve its customers’ experience through collecting data and reducing downtime where possible.

Read moreHow Industry 4.0 will reinvigorate UK manufacturing

I n manufacturing technology, there is a current trend in data exchange and automation called Industry 4.0 (pronounced four point zero). It mainly comprises the internet of things, cognitive computing, cyber-physical systems, and cloud computing. Industry 4.0 is also called the fourth industrial revolution. Industry 4.0 is about digitisation that brings the physical and virtual worlds closer together. This ensures that each learns from one another. Although Industry 4.0 has set out to transform how companies approach business, the UK is lagging in this. As a result, it has a hurdle to climb to keep up with other European countries and other international countries.

Midlands based Pressmark joins leading industry network

Pressmark Pressings has joined the leading Midlands manufacturing and engineering membership group Made in the Midlands (MIM).

Pressmark celebrates MBI anniversary with £2m sales boost

A Warwickshire-based metal forming specialist is celebrating a major transformation in fortunes just one year after a Management Buy-In (MBI) was completed with a sales boost.

FMEA & FEA – impact on Aerospace & Defence Manufacturing

Aerospace & defence manufacturing usually commands a lot of expertise, as both industries deal with production of systems with both complex designs and functionality. Therefore, their entire manufacturing processes are carried out with an extra level of precision, since any small defect will inevitably lead to the loss of multiple lives.

For instance, whenever aircraft are in the air, the lives of those in it are solely dependent on how well the systems of the aircraft were designed, developed and manufactured. Any minor errors that are made during the design, development or manufacture of any one of the thousands of components in the aircraft, will potentially lead to a significant number of fatalities. The same applies to any of the defence vehicles which are used by our military personnel, where the lives of the men and women in uniform using them, are dependent on how well these machines were designed, assembled and tested.

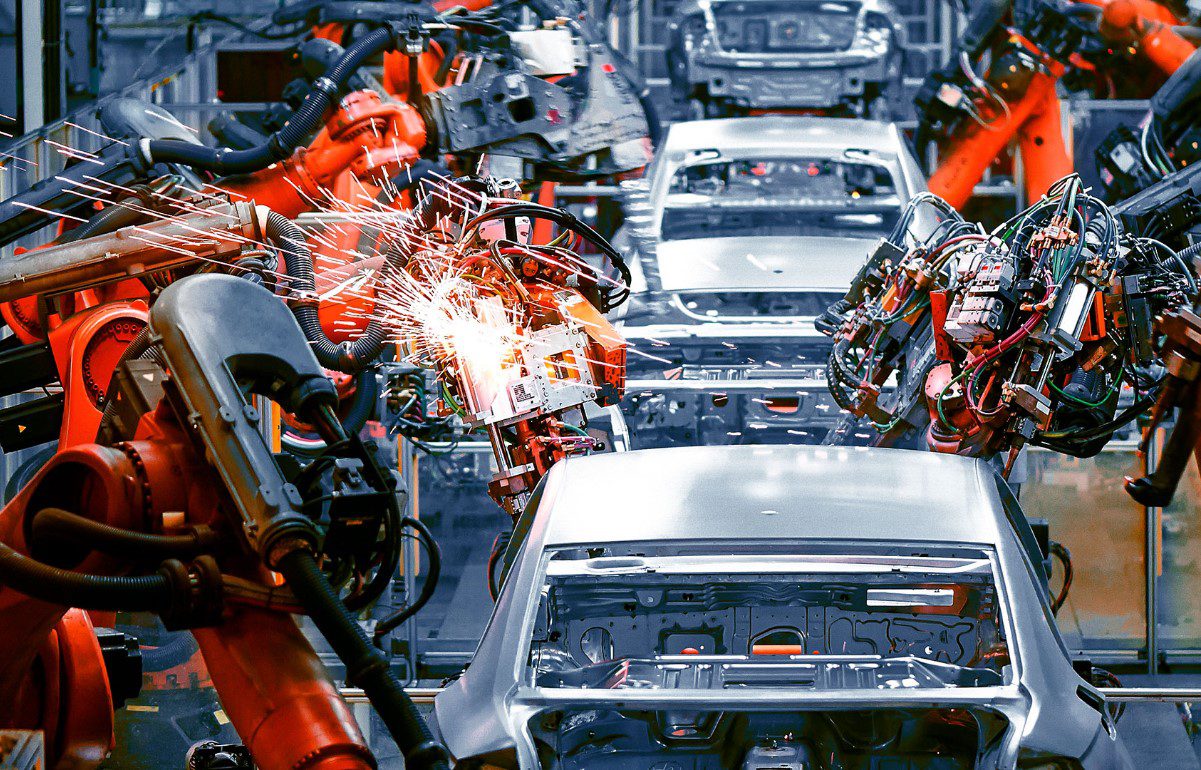

Chassis Manufacturing Process

A vehicle frame forms the basis of an automobile which, known as the chassis, this frame supports the sub-assemblies and other components of the car. The chassis also provides stability to the car from the variety of forces and impacts that it has to sustain throughout its life. The construction of the frame is of a uni-body type in the case of passenger cars and most commercial vehicles, such as trucks, are produced with a body-on-frame construction.

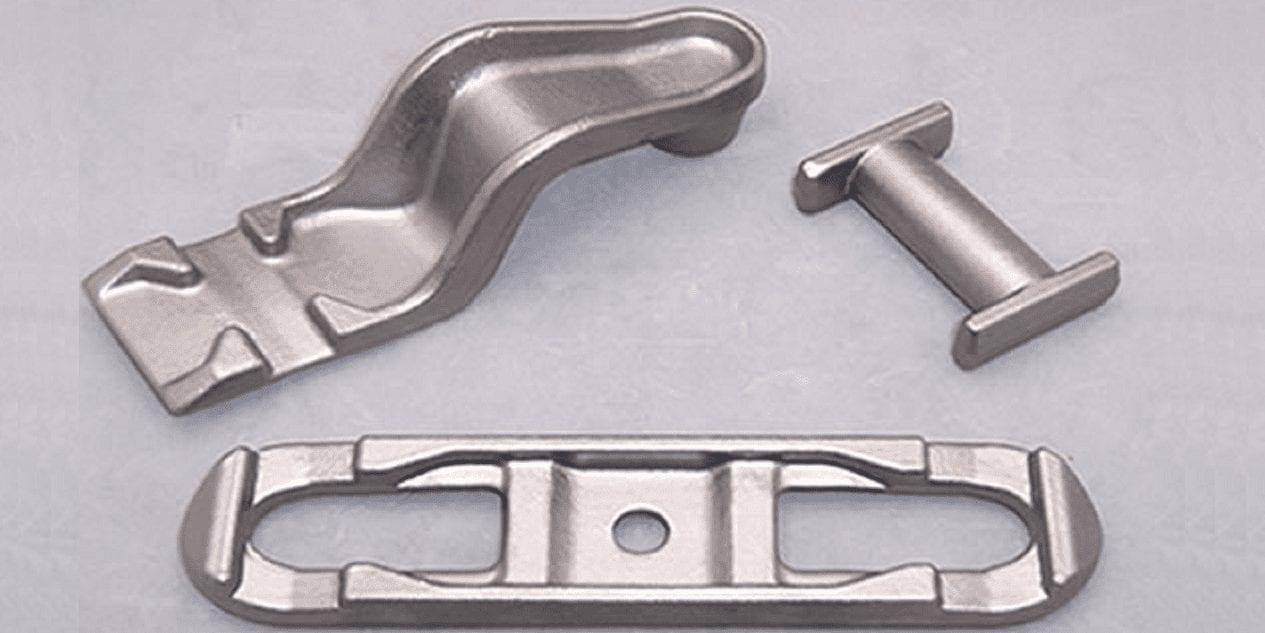

How Pressings are Replacing Forgings and Castings

The automotive industry is continuously changing. One of the most significant new focuses is reducing the weight of materials used in the construction of vehicles. Pressings are produced by stamping, and this method replaces some of the manufacturing methods from the past.

Materials and Manufacturing Education

Materials and manufacturing processes remains an essential component of industrial design education. But for many students and young designers, they are still unsure of their comfort with these complex issues and how they affect their designs.

Sandstone to Pressmark – the acquisition

After many months of arduous due diligence, the Napier team from Left Hand Press finally acquired 90% of Pressmark Pressings. This project has the codename, Sandstone. The group, which Alan Gardner has led through the acquisition, brings a wealth of experience to Pressmark. Chairman Les Wilkins will lead the team, bringing exceptional experience from the press industry, which has evolved over 40 years. In addition, Les has headed up OEM plants for Rover and BMW. In addition, he has managed significant tier 1 plants and worked as a consultant for automotive OEMs in Japan and China. When questioned about the acquisition, Les said, “Pressmark is an excellent company with many opportunities.

I am looking forward to working with the team to develop this further. We want to build on the excellent reputation of Pressmark for Quality, Cost and Delivery.”

Heading up the executive team will be Chief Executive John Nollett. He brings a wealth of knowledge from the manufacturing sector. John is directly involved in the design, manufacture and assembly for automotive OEMs. On speaking with John, he talked about the opportunity saying, “I have been fortunate enough to have spent some time with the existing team at Pressmark, learning about their capabilities. I can honestly say that the company has the fundamental structure needed to develop this business further. The team here are great! I look forward to developing strong relationships with them and our Customers and suppliers to drive this business forward.” He went on to say, “This is a great acquisition. Based in Atherstone, Warwickshire, we are ideally situated to fulfil the needs of the UK manufacturing sector. There is a great automotive and manufacturing heritage locally within the Midlands Engine. It will be fantastic to draw upon that experience as we grow our business here in the Midlands.”

Finally, Alan Gardner brings significant change management experience and financial expertise, where he worked at the partner level within KPMG. Alan has had a lot of experience working alongside manufacturing businesses. Holding the position of Finance Director, Alan spoke of the deal, saying, “Pressmark is an ideal acquisition for Left Hand Press, as it brings a variety of large bed presses with ample free capacity to grow the business, not only in the automotive sector, where it is strong but other sectors too. With our financial support, along with the experience that both John and Les bring to the team, I am excited about the future for Pressmark.”